screen printing screen frame

Screen printing is a popular technique used to transfer ink onto a surface through a specially designed screen. The screen frame is an essential component of screen printing, as it holds the mesh in place and provides a stable surface for printing. In thiScreen printing is a popular technique used to transfer ink onto a surface through a specially designed screen. The screen frame is an essential component of screen printing, as it holds the mesh in place and provides a stable surface for printing. In this article, we'll take a closer look at the screen printing screen frame and its important features.

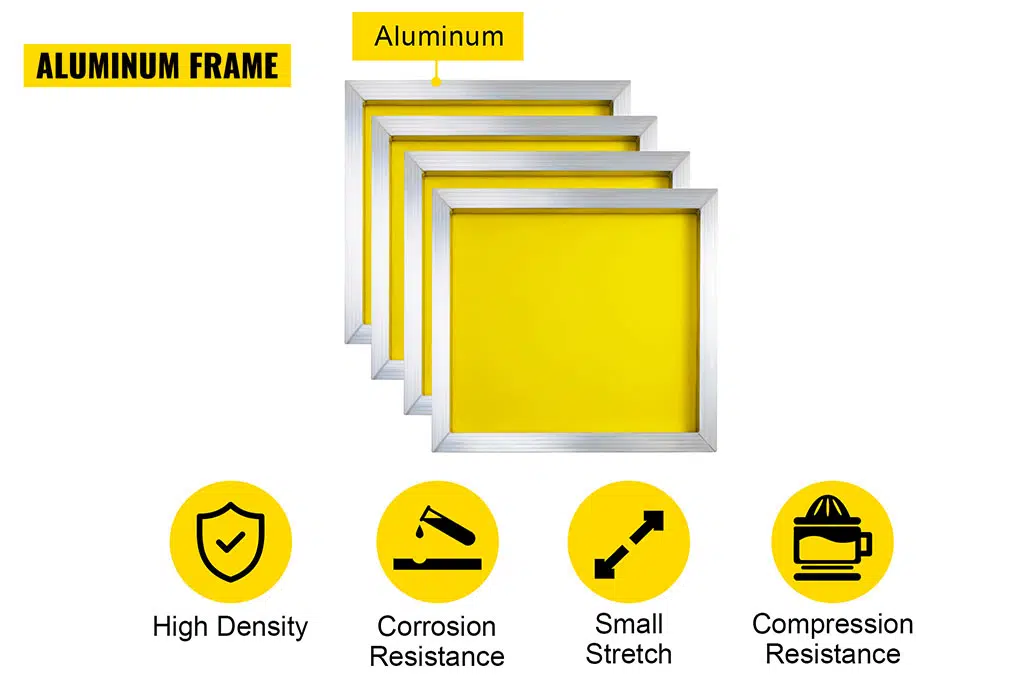

A screen printing screen frame is typically made from wood, aluminum, or steel. The frame is designed to hold the mesh in place and ensure that it is taut and stable during printing. The size and shape of the frame will depend on the size and shape of the design being printed and the surface it is being printed on.

The most common screen printing screen frame material is wood. Wood frames are affordable, easy to work with, and provide a stable surface for printing. They are available in a range of sizes and can be easily customized to fit specific project requirements. Wood frames are also suitable for most types of inks and designs.

Aluminum and steel frames are more durable than wood frames and are ideal for high-volume printing or printing on large surfaces. They are more expensive than wood frames but can be reused multiple times without warping or bending. Aluminum and steel frames are available in a range of sizes and are suitable for most types of inks and designs.

The tension of the screen mesh is critical for achieving high-quality prints, and the screen printing screen frame plays a crucial role in ensuring that the mesh is taut and stable. The tension is determined by the amount of force applied to the mesh when it is stretched over the frame. A high tension ensures that the ink is applied evenly and consistently across the surface being printed, while a low tension can result in ink bleeding or smudging.

To achieve the proper tension, the screen mesh is attached to the screen printing screen frame using a specialized adhesive tape or glue. The mesh is then stretched tightly over the frame and secured in place using tension rods or clamps. The tension should be adjusted periodically throughout the printing process to ensure that it remains consistent.

In conclusion, the screen printing screen frame is an essential component of the screen printing process. The frame provides a stable surface for printing and ensures that the mesh is taut and stable. Wood frames are the most commonly used frames and are suitable for most types of inks and designs. Aluminum and steel frames are more durable and ideal for high-volume printing or printing on large surfaces. The tension of the mesh is critical for achieving high-quality prints, and the tension should be adjusted periodically throughout the printing process to ensure consistency.

Tags: